Masina de curatat pe transversala cu perii tip Kullen-Koti RBM

- This KULLEN solution provides efficient through feed cleaning of different linear moving surfaces

- In a wide range of different materials by means of transverse brushing.

- It effortlessly removes loose particles such as dirt, dust, granulate or light metal parts.

- Surface cleaning of items such as conveyor belts

- Surface cleaning of chipboard panels, sheet metal strip or foil webs

- Fine dust removal and transportation of objects with sensitive surfaces

- Either in a horizontal, vertical or inclined position.

- Avantaje

- Excellent cleaning results due to transverse brushing system

- Cost efficient in terms of energy (electrical power and suction air)

- Individual configurations to address customer-specific needs

- Easy retrofitting on existing plants

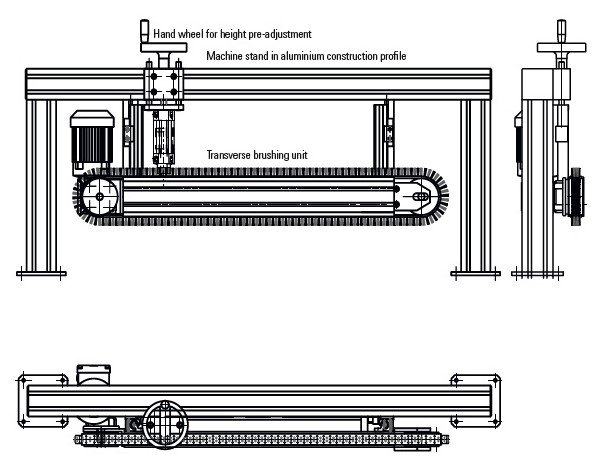

- Machine stand in durable anodized aluminiu construction profile

- Integrated height adjustment

- Hand wheel pre-setting, precision adjustment, e.g. by means of pneumatic cylinder actuation in the working and idle position

- Special features

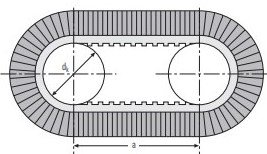

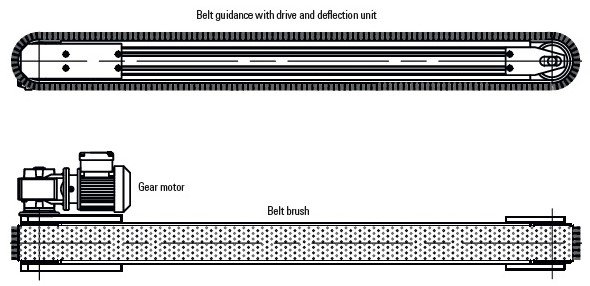

- Depending on requirements, belt brushing machines can be used with either flat or toothed belts.

- The most cost-effective alternative for cleaning purposes is to use a flat-belt brush.

- The fill density is greater in flat belts than toothed belts, and can be individually determined.

- More effective cleaning result is achieved when using a transverse brushing system with belt brushes compared to roller brushes.

- Energy requirement for driving the belt and the volume of suction air required is at least 50% lower than for roller brushes.

- Toothed-belt brushes are used in transport and feed technology applications, ensuring cycle time precision and backlash-free drive.

- When selecting toothed belt dimensions, the pitch and standard belt width must be taken into consideration.

- We will be pleased to provide you with expert in-depth advice.

- Natural and synthetic bristles with a thickness of up to 0.6 mm are used as filler materials. In exceptional cases, different

Date tehnice

| Latimea maxima de lucru | 4000 [mm] |

| Latimea maxima a periei | 200 [mm] |

| Tip de banda de perii | Optional: banda plata sau dintatat |

| Perii banda circulara | Optional: fire naturale sau sintetice |

| Grosimea filament | maximal ∅0.60 mm |

| Alimentare motor angrenare | 230 V sau 400 V la 50 Hz |

- When using this type of brush, the necessary fill density and belt width can be ideally selected for the specific brushing task.

- KULLEN recommends using either a chrome leather belt with polyamide insert, or a fabric belt.

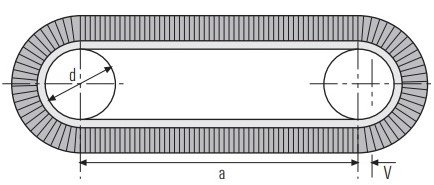

- In either case, different belt widths and qualities are available, resulting in different minimum drum diameters.

- These belts are temperature resistant between -15°C and +80°C.

- The belt width can be selected between 20 and 200 mm, corresponding to a fill width of 10 to 190 mm.

- Depending on the application, users may opt either for a compressed surface or block fill.

- In this case, the bristles can be arranged vertically, pitched, in echelon formation or with different heights.

- Flat belt brushes offer the greatest scope for variation of the fill density, ranging from extremely low to extremely high.

- KULLEN will naturally be pleased to advise you on the best solution for your needs

- Toothed-belt brushes from KULLEN offer a decisive benefit over flat belt brushes.

- Due to their positive locking design, they can either be driven synchronously or set to a precisely measurable cycle time.

- This is an essential condition for applications involving feed technology.

- KULLEN standard toothed belts made of polyurethane with steel cord and specially welded studs for fixing the fill material.

- These brushes are temperature resistant between -30°C and +80°C.

- Depending on the toothed belt pitch (T5, T10, T20), belt widths of between 6 and 150 mm can be used.

- The resulting fill widths are between 2.5 and 142 mm.

- Depending on requirements, synchronous pulleys are supplied with or without flanged wheels.

- By using different fill height arrangements, it is possible to create conveying areas adjusted in line with the transported product.